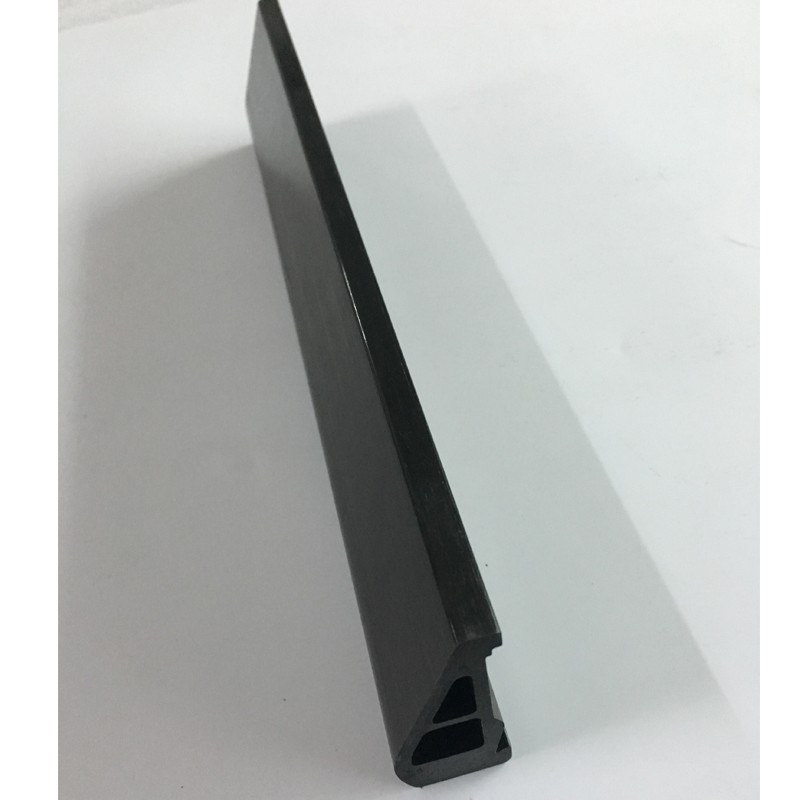

China Profesional Factory of I-Shaped bar Carbon Fiber Profile

- Place of Origin:

-

China

- Brand Name:

-

Tstar

- Application:

-

Other

- Shape:

-

Carbon Plate, customized

- Dimensions:

-

Customized

- Product Type:

-

Carbon Fiber

- C Content (%):

-

98%

- Working Temperature:

-

120

- S Content (%):

-

0.5%-5%

- N Content (%):

-

O.0015

- H Content (%):

-

O.1

- Ash Content (%):

-

0.25 <0.5%

- Volatile:

-

Non-volatile

- Material:

-

65% carbon fiber, 23% resin & 2%filler

- Color:

-

Black or customized

- Dimension:

-

customized

- Length:

-

custom, tolerance±0.03mm

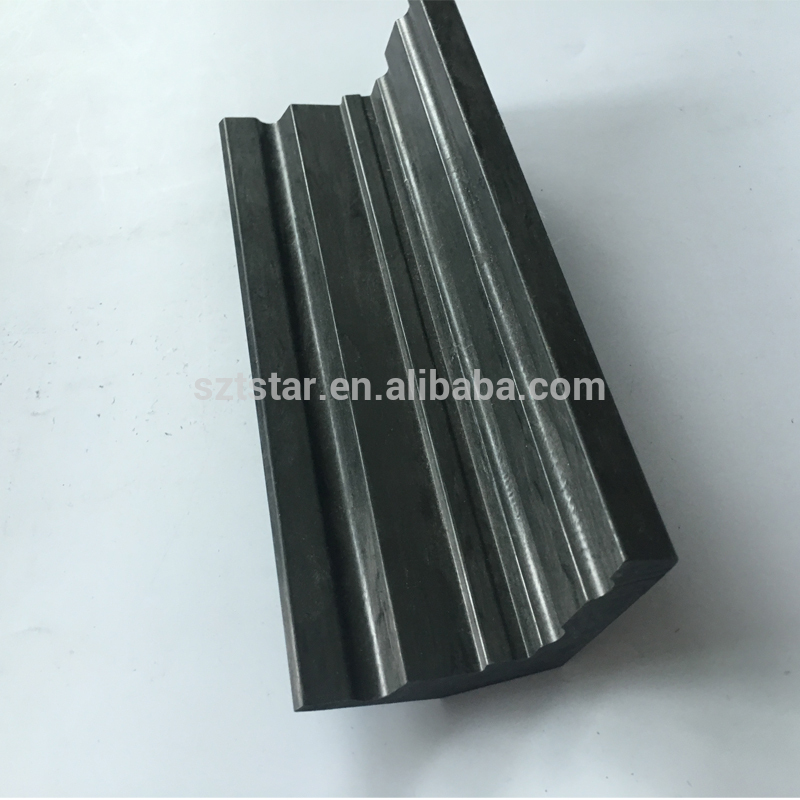

- Craft:

-

pultrusion & moulding, Laminated

- Composite Type:

-

unidirectional orientation

- Density:

-

1.48g/cm3

What is carbon fiber profile

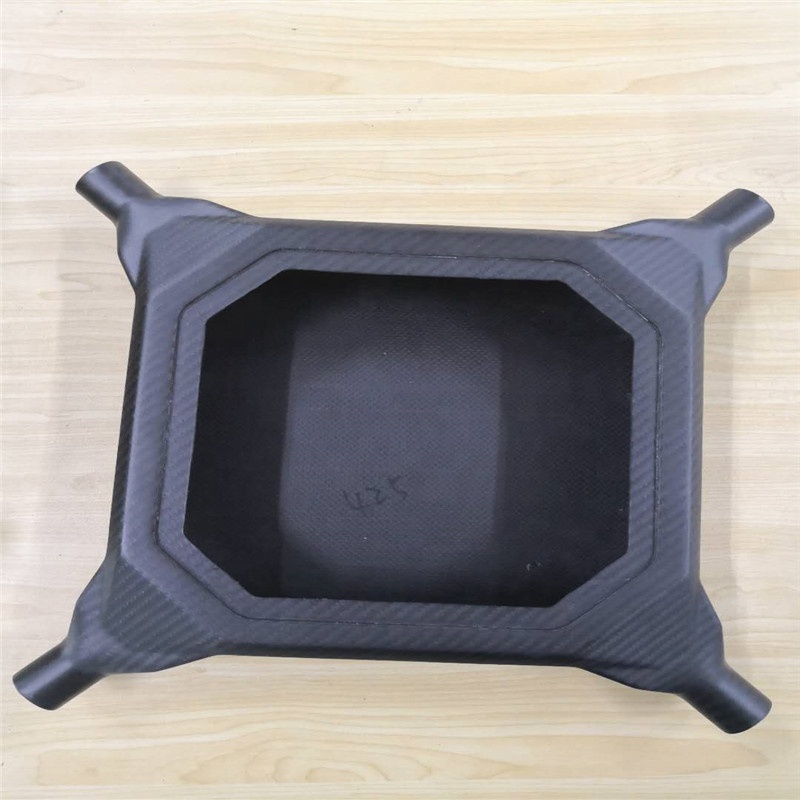

Carbon fiber profile has extremely high strength, light weight, with shiny and clear appearance, widely used for model helicopter parts and hobby market. It can be made into pure carbon fiber or glass fiber core with carbon fiber surfaces, thickness range from 0.2mm to 10mm, customized thicknesses and sizes are available. Stand for complete solution, we supply full size to pre-cut panel, as well as CNC machined parts to your specification.

Advantage of carbon fiber profile

1. Light weight and high strength: The strongest of all commercial reinforcing fibers in tension. Especially good for the tension skin on cored composite laminates.

2. Excellent corrosion resistance: Used in reinforcing resin, carbon has good alkaline resistance as well as resistance to salt water and many other chemical environments.

3. Excellent fatigue properties: Used as a primary reinforcement for fatigue prone products such as helicopter and wind turbine blades as well as off shore power and sailboats.

4. Excellent compression properties: Proper fiber sizing for the resin matrix selected can yield impressive compressive properties but this quality can be quite difficult to measure with standard.

Carbon fiber product is suitable for:

1. The remedy repair and strengthening of the plate and beam of concrete structures;

2. The strengthening of openings around the wall and plate;

3. The strengthening of beans of wooden buildings;

4. The strengthening of bridge plate ,bridge pier and girder;

5. The remedy repair and strengthening of tunnel and cable lines etc.

We engage in the developing, producing and sales of high quality fiberglass and carbon fiber products, OEM is welcome. The manufacturing process is various, range from pultrusion, roll-wrapped, moulding press, BMC&SMC, and pullwinding, etc. Most of the products widely used in construction, equipment (sport equipment, medical equipment, electrical installations, facilities for transport and communication, etc. ), construction (used as for scaffold, beam, and support columns, etc), railway, subway, coal mining, auto parts, handles, UAV/drones, RC plane model, supporting, X banner, etc. We make drill holes, chamfer, CNC cutting, silk-screen/labeling logo, etc. Fiberglass and carbon fiber is a new composites products, it is much lighter and stronger than metal, stainless steel, bamboo, wooden, etc.

We have the latest equipment, professional technology and top service team. Our products have pass SGS, ROHS, and ISO. Our motto is ‘best quality, customers first, competitive price’, we have exported so many fiberglass and carbon fiber products all over the world for years. We will provide all the customers with high quality fiberglass and carbon fiber products.

Q1. What is your terms of packing?

A: Generally, small size products we will use carton,and the products with paint will cover by plastic film,and thelong products pack by woven belt.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance. Small amount 100% before production.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.