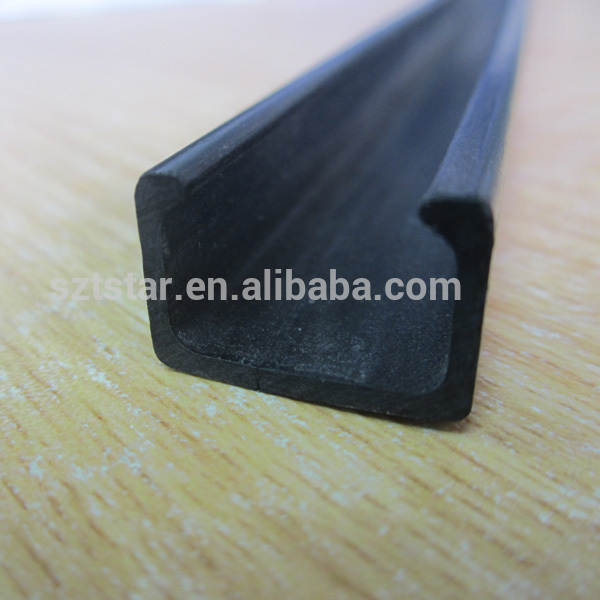

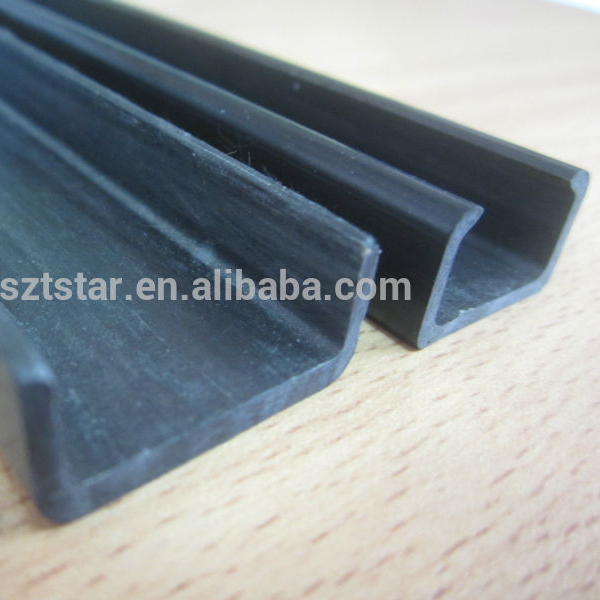

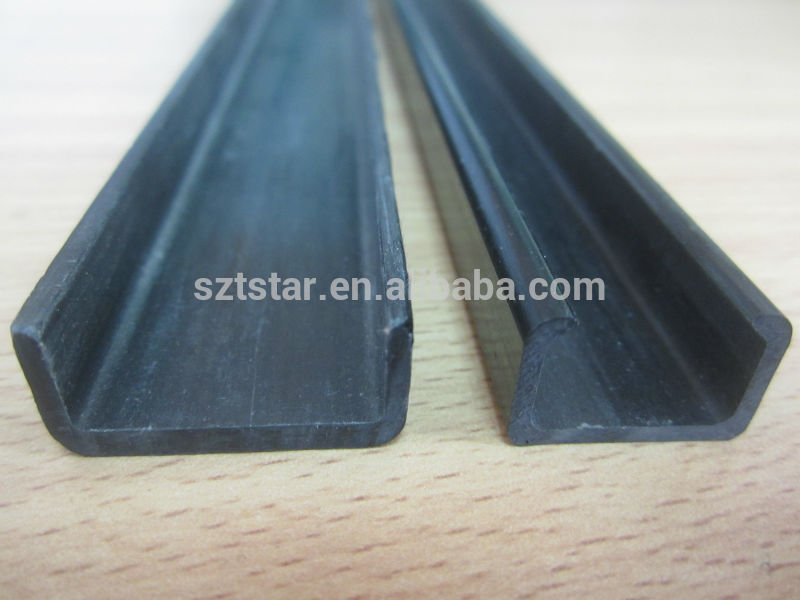

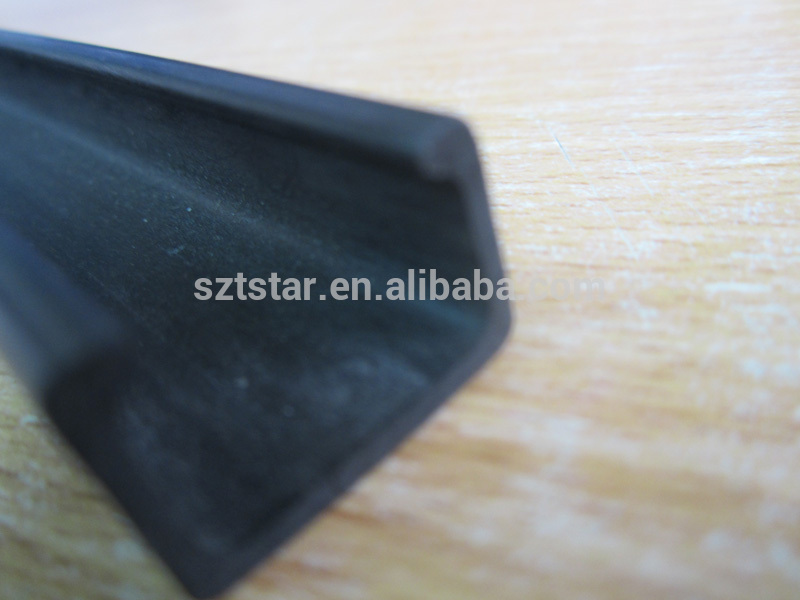

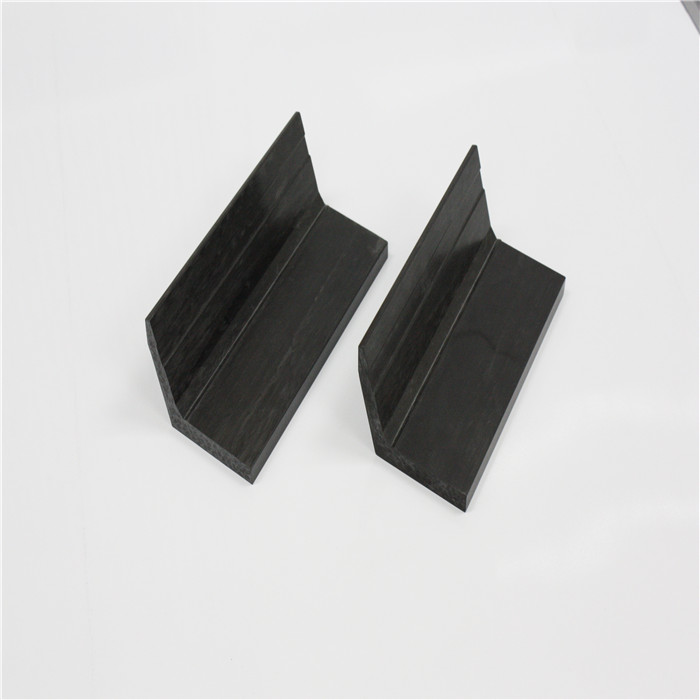

Corrosion resistance pultrusion full carbon fiber U channel shaped profile

- Place of Origin:

-

Guangdong, China

- Brand Name:

-

T-star

- Application:

-

Industry,sports,entertainment,etc.

- Shape:

-

Round,square,customized

- Dimensions:

-

Customized

- Product Type:

-

Carbon fiber tube

- C Content (%):

-

100

- Working Temperature:

-

120

- S Content (%):

-

0

- N Content (%):

-

0

- H Content (%):

-

0

- Ash Content (%):

-

0

- Volatile:

-

Non

- Length:

-

Customized

- Surface:

-

Matte or glossy

- Color:

-

Black

- Thickness:

-

Customized

- Diameter:

-

0.4-200mm

- Certificate:

-

ISO9001, SGS, ROHS

1000000 Piece/Pieces per Month

Packaging Details:Usually, small size products we will use carton,and the products with paint will cover by plastic film,and thelong products pack by woven belt, but we will confirm the packing details with you before shipping.

Port:Shenzhen

Lead Time:7 to 25 working days

Corrosion resistance pultrusion full carbon fiber U channel shaped profile

Advantage of carbon fiber profile:

1. Light weight and high strength: The strongest of all commercial reinforcing fibers in tension. Especially good for the tension skin on cored composite laminates.

2. Excellent corrosion resistance: Used in reinforcing resin, carbon has good alkaline resistance as well as resistance to salt water and many other chemical environments.

3. Excellent fatigue properties: Used as a primary reinforcement for fatigue prone products such as helicopter and wind turbine blades as well as off shore power and sailboats.

4. Excellent compression properties: Proper fiber sizing for the resin matrix selected can yield impressive compressive properties but this quality can be quite difficult to measure with standard.

Carbon fiber products are mainly applied to uav machine arm, body, CNC matrix carbon fiber board, robot, automobile, motorcycle, helmets, roadblocks, photographic equipment, paddle, cycling, badminton racket, fish sticks, electric skateboards, fish guns, bow and arrow shaft, fishing gear, sports backpacks, decorative shell, etc;

Tstar composites is a manuacturer with more than 10 years of experience in the field of carbon fiber products and fiberglass products.

We engage in the developing, producing and sales of high quality fiberglass and carbon fiber products, OEM is welcome. The manufacturing process is various, range from pultrusion, roll-wrapped, moulding press, BMC&SMC, and pullwinding, etc. Most of the products widely used in construction, equipment (sport equipment, medical equipment, electrical installations, facilities for transport and communication, etc. ), construction (used as for scaffold, beam, and support columns, etc), railway, subway, coal mining, auto parts, handles, UAV/drones, RC plane model, supporting, X banner, etc. We make drill holes, chamfer, CNC cutting, silk-screen/labeling logo, etc. Fiberglass and carbon fiber is a new composites products, it is much lighter and stronger than metal, stainless steel, bamboo, wooden, etc.

Workshop

Showroom