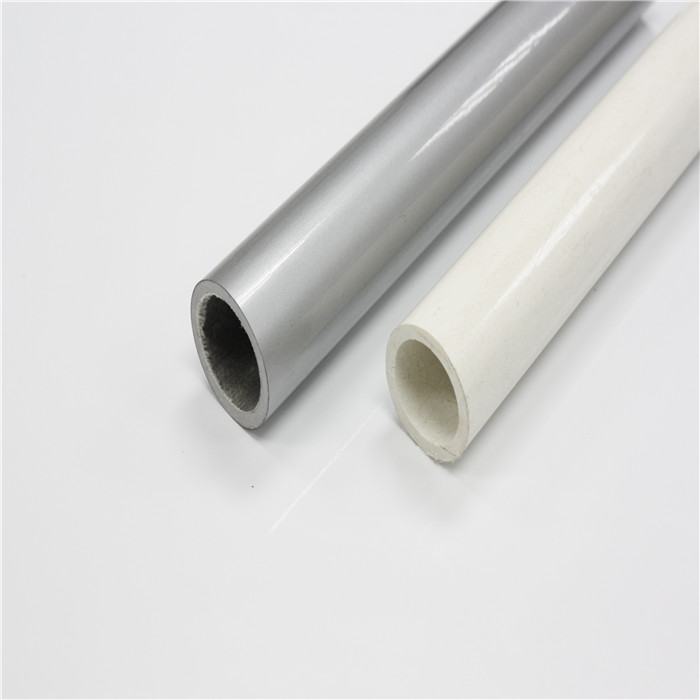

GRP Pipe Specification, RTR Pipe

- Place of Origin:

-

Guangdong, China

- Brand Name:

-

Tstar.

- Model Number:

-

FRP Tube-01.

- Application:

-

Various.

- Surface Treatment:

-

Smooth.

- Technique:

-

Pultrusion.

- Dimensions:

-

Customized are accepted.

- Product name:

-

Pultruded Fiberglass Pipe

- Color:

-

All colors are available.

- Tolerance:

-

±0.5mm.

- Sales Type:

-

Manufacturer.

- Type:

-

Adjustable.

- Length:

-

Customize as per you require.

- Shape:

-

Round,square,ect.

- Mark:

-

Customize.

- Material:

-

65%fiberglass&33%resin&2%filler.

- Feature:

-

Corrossion Resistance

Durable Fiberglass Tube

Welcome to visit Tstar factory

Shenzhen T-star Composites Co., Ltd. is a professional manufacturer of carbon fiber and fiberglass products, dedicated in design, development, production and sales of composites products for more than 10 years.

|

Item | Fiberglass Tube |

| Materials | Fiberglass | |

| Technology | Pultrusion | |

| Length | Customized | |

| Shape | Round, square or rectangular | |

| OEM | Accepted |

Advantage

- a. Long service life,light weight,low price;

- b. Anti-aging,anti-corrosion,abrasion-resistant;

- c. High strength,heat-insulation,heat-resistant;

- d. Waterproof,eco-friendly,etc.

Compared to other products

- It is flexible and can be easily designed as various size, length in a colorful way. And you can sufficiently choose the filling materials accroding to your product’s special application.

ROUND FIBERGLASS TUBES

- Antenna Housings

- Lawn Garden Tool Handles

- Snow Shovel Handles

- Paint roller Handles

- Mop/Broom Handles

- Professional Service Tools

- Arborist Tools/Tree Pruners

- Railing Systems

- Construction

- Telescoping Tools

- Flag Poles

SQUARE FIBERGLASS TUBES & RECTANGULAR FIBERGLASS TUBES

- Insulators

- Railroad Cross Arms/Gates

- Spacers

- Structural Supports

- Framing

- Construction

- Architectural

- Bench Slats

|

>> Click here to get catalogues now Tstar is also quite experienced on OEM & ODM cooperation with customers for personalized products, all new ideas are welcome here. |

Pultrusion is a continuous process for manufacturing composites with a uniform cross-sectional shape. Fiber reinforcement is pulled through a resin-impregnation bath and into a shaping die where the resin is subsequently cured, or set. Heating to both gel and cure the resin is accomplished within die length. Pultrusion yields continuous lengths of material with high unidirectional strengths.

Manufacturing Equipment

>>Click here to contact us now

If you have any enquiries about our products, please feel free to contact us and we will be more than glad to be at your service.